By Johanna Loomis, Lead Industrial Designer

Industrial Design Process in a mid-stage start-up surrounding

Physical Interaction is a significant part of the Holistic User Experience

In the past, I have worked for Design Agencies and Consultancies. In this context, the start-up projects have always been the most exciting. They are innovative, daring and the trial-and-error approach is the most satisfying process, it is ten times faster and requires a hands-on mentality.

In the Vay universe, there are many more physical interactions than you might think. For example, we are facing the question of how does the teledriver hand over control and liability of the vehicle to the user? This doesn’t necessarily have to be a physical interaction, but it could be! To figure out these kinds of mini-interactions in the customer journey, discovering the happy paths and pain points together with UX research, UI/UX, communication design, and also with the engineering team is crucial for the final product and service.

Clients nowadays do not accept mediocre thought-through interactions anymore, they become impatient by the sheer amount of alternatives, so the user has to be involved at a very early stage.

The power of Collaboration

Projects are initiated from both sides, Engineering and User Experience, which makes us equal on every level. Still, it can be challenging to fight for the user’s needs in a meeting with five engineers and one designer. But the discussion is worth it and it will definitely pay off in the end.

We teach each other about different tools, programmes and technologies. For example, I taught the Engineers hand sketching to express their ideas faster and more precisely. In a very heterogeneous team, coming from different cultural backgrounds, adding another language is very helpful to communicate and collaborate. As we move through the design process, we develop the technical package and design surfaces with applied brand design elements simultaneously, which is very efficient. During the projects, we always ensure quick responsiveness and short feedback cycles, repeated UX tests and design reviews with all relevant stakeholders. Conducting retrospectives on ID & Engineering Cooperation gives us the opportunity to understand what went well and what could possibly be adjusted in the next phase.

Speaking of challenges… Innovative development projects essentially have a short life cycle and the technical components are constantly changing, which means that the design has to be adapted several times to new circumstances. This doesn’t necessarily make the design better, but it is a chance to iterate on the run.

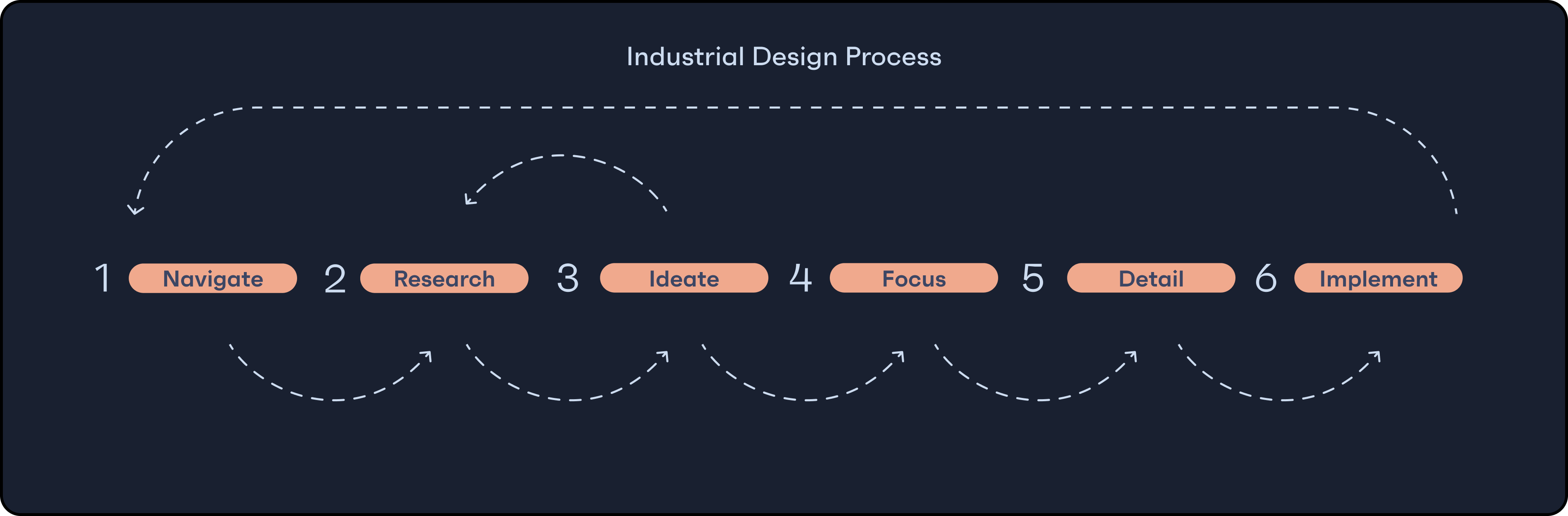

Iterative & streamline Design Process

Over the years of working with different organisations, I discovered that my best practices are applied within a design process based on the streamline idea. It follows a path that is not perfectly linear but flows with iterations. It is not as repetitive as a digital design process, because it would be far too expensive and time-consuming to create high-end physical prototypes multiple times.

The projects in the Vay universe are so different that the process has to be adapted a little each time. I will describe roughly how we approach requests for Industrial Design:

- Navigate through all project conditions. Have a briefing template filled out by the requester. Collect requirements from all stakeholders, like Engineering, PM/TPM, Legal/Safety and scrutinise the UX requirements. Hold a kick-off meeting with all of them to get aligned on expectations and timelines.

- Always start with research and discovery to comprehend what the desired product is. What are the technical requirements and how solid is the internal package, are there opportunities for improvement? What is the context and how is it used and by whom? Work directly with the internal UX Researcher if needed. If you understand the product and can put yourself in the user’s shoes, the result will be better before the project has even started.

- Mini Thumbnail sketches help with ideation to get an idea of the shape and where brand-specific design elements could be placed. Always keep your Design language vision and strategy in mind!

Do you need technical solutions first? Teach your engineers how to draw and hold a workshop to gather their precious ideas as well. Do quick prototypes to figure out ergonomics, working principles or depending on the project, do role games with colleagues through the Customer Journey to get an idea of whether users would understand your intent.

After rough idea sketching, choose your favourite basic ideas and start sketching them out in more detail. Make 3-4 sketches to have variations and try out some things. This can be done with paper and pen or use a digital sketchpad to easily revise details. Because this will not be your last sketch. - If you now have to focus and decide on one design it can get tricky. There are different methods to find the right design, but if you have written down and weighted certain factors beforehand, it is quite easy to judge which design is best suited for your application.

Revisions and iterations will keep coming up while discussing the results of 2-3 designs with all stakeholders. To help them understand the idea it helps to have some more high-end digital sketch-renderings in different perspectives and in application to understand the proportions and impact. - When a decision has to be made, get into detail. Things get real in 3D. Surfaces are being defined and technical requirements, distances, material limitations are set.Based on the 3D Structure colours, materials and surfaces can be defined. At the same time the Mechanical Engineering team takes over the surfaces to add the construction framework and final technical intervals.

New prototypes are printed/built and functionality can be tested, as well as the design appearance. These “Look-like-works-like” prototypes can be tested by both engineers and users. - Iterations in design as well as in Engineering are being done until the perfect product is being built in. Design quality checks are made after each revision. Then the tooling (if needed) and production can get started.

Industrial Design Strategy

My current role at Vay is to create a strategically based Industrial Design Style Guide which is derived from the Brand Strategy. The challenge is that we are not building cars, but using an existing platform, which already provides a certain design, which does not correspond to our DNA.

We are not the only ones facing this challenge. Thule is one example of a design-driven company who puts function in the foreground and their styling plays a subordinate role. Yet, their products are distinguishable and recognizable. That is exactly the question we are facing with our exterior as well as car interior attachments. Do we want to integrate them and be inconspicuous, or do we want to stand out from the platform and be loud and striking? Rest assured – we are on it.

Having agreements, principles and design elements defined, helps us:

- to be consistent in our design quality, to communicate with external parties about expectations

- to create an emotional bonding with the customers through repetitive visual cues

- to shape Holistic Experiences though great and recurring experiences over several channels and touchpoints

Design Management starts even before the process shown here. It is also about finding the right balance for project planning and not prioritising too strictly, because the circumstances can change anytime. Flexibility in project management is crucial in a start-up, but also being visible and playing an active role in project planning to create value and to make design relevant.